When and how to service your trencher - Trencher Servicing and Maintenance

Service

and oil change

1.

Change the gear oil within the first 30 hours of extreme work,

within 50 hours of moderate work or otherwise within the first 3 months.

2.

After the first service, the gear oil must be changed every

300-500 hours

3.

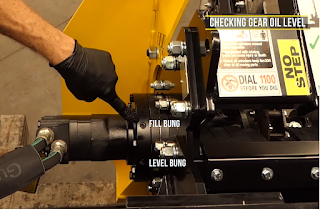

Check your gear box oil level every 10 hours of operation:

Locate the level bung at the 2 o’clock position and make sure that the fill

bung is centred and the trencher level. Top up your gear oil through the fill

bung until the oil can be seen exiting the level oil

3.

Check your gear box oil level every 10 hours of operation:

Locate the level bung at the 2 o’clock position and make sure that the fill

bung is centred and the trencher level. Top up your gear oil through the fill

bung until the oil can be seen exiting the level oil

4.

Carry out a full service every 12 months by a trained and

authorised Digga technician

Pre-operational

checks

1.

Visually inspect your trencher and components

2.

Check that all nuts and bolts are in place and properly

tightened

3.

Check all fittings and hydraulic hoses are tightened and secure

4.

Check that safety stickers are in plain sight and legible

5.

Check externally for any oil leakage around hoses, fitting,

motor and gearbox.

6.

Check any war and tear on linkages and pins, chains and teeth

Adjust

your trenching depth

Once unbolted, you can remove the skid plate and rotate until

the mounting the holes line up with bolts again at your desired depth setting

(refer to your operator’s manual for depth charts and further information

Refit

washes and nuts and tighten.

Adjust

your trencher chain

1.

Remove the 14mm bolts holding the adjustments spanner to the

trencher boom

2.

Use the adjustment spanner to turn and adjust the nut clockwise

for loosening or anti-clockwise for tightening

3.

To achieve the correct chain tension, check the adjustment at

mid-way point of your chain. Allow for 20-30mm of vertical movement between

chain and boom.

In our video, Mark takes you

through all these steps.

For further questions and replacements of worn parts please contact our service department through info@digga.com or 1300 2 DIGGA

For further questions and replacements of worn parts please contact our service department through info@digga.com or 1300 2 DIGGA

Trencher

wear parts – what to consider

Trencher teeth wear on the tip and side bulge in

varying amounts. In the video below, Anthony covers the different wear parts on our

range of trenchers, so you can work more efficiently for longer.

When do I need to exchange my trencher teeth?

Keep an eye on the wear of your trencher teeth, as this will affect your trenching efficiency over time. Worn teeth will start to inhibit the ability of the chain to penetrate the ground, meaning you’ll just be labouring your machine up and burning extra fuel.

To make sure this doesn’t happen, watch Anthony explain how to determine when the trencher teeth are worn out.

Comments

Post a Comment