Understanding Digga excavator hitches

Digga manufacture a range of excavator hitches for machines up to 90 tonne. They were designed and manufactured to improve operator and workers safety when manoeuvring around sites whilst also providing a simpler connection to augers and piles. All our hitches are custom made to your machines requirements and vary in suitability depending on your use.

Here are some key advantages of each of our excavator hitches and an explanation on how to submit an order.

Digga excavator hitches

Digga single pin hitch

The single-pin hitch is suitable for excavators using smaller drives. It is a light weight, non-bulky option for smaller machines. This hitch can be used to fit Digga PDD to PD3 drive units on micro or mini excavators up to 3 tonne.Its weight and size make it easy to transport, fit and offers a financially economical option.

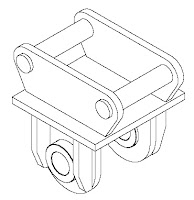

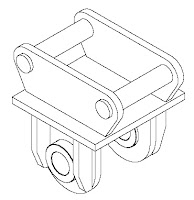

Our standard configuration, double-pin excavator hitch. It can be used on all excavators as it has the option to choose loose or fixed pin.

The double pin fixtures make it ideal for augering and screw anchoring in all ground conditions. It is suitable for all drive unit ranges from PDD to PD50, Supa Drives, Mega Drives, Ultra Drives and Xtreme Drives.

The excavator cradle hitch was designed to provide a simpler connection to augers and piles and make it easier to manoeuvring around work sites safely; giving you better control when moving around the job site as the cradle supports the drive.

It is available with loose pin or fixed pin options and suitable for PDD – PD50 drives. There is more information on the benefits of using the Digga cradle hitch, here.

The ryno hitch was designed to handle the torsional loads of anchors and screw piling. It has a fully engineered, extra heavy duty design and manufactured from premium grade steel.

The piling hitch cradles the drive in 3 different positions to give better control and manoeuvrability when moving around the job site as well as easier connectivity to augers and screw piles.

As it has been designed for screw piling, it is suited to larger drive units from PD12 – PD50, Supa Drives, Mega Drives, Ultra Drives and Xtreme Drives.

There is more information on the benefits of using the piling cradle hitch, here.

Ordering your excavator hitch and supplying the correct measurements

When you’re ordering a hitch for your attachment it’s important you supply the correct details to ensure your hitch fits the machine and application.

You will need to take some measurements of bucket and supply: machine make and model and your Digga attachment part number.

To order your excavator hitch you can complete the details on the Digga website, here.

See the reference diagrams below. These are also available within the online order form and highlight where to take the measurements from.

C. Front pin diameter

Here are some key advantages of each of our excavator hitches and an explanation on how to submit an order.

Digga excavator hitches

Choosing from Digga’s range of excavator hitches will vary based on the application and attachment, and your machine. Below are 4 of Digga’s excavator hitches which are fully engineered and manufactured at our Yatala facility in Queensland.

Digga single pin hitch

The single-pin hitch is suitable for excavators using smaller drives. It is a light weight, non-bulky option for smaller machines. This hitch can be used to fit Digga PDD to PD3 drive units on micro or mini excavators up to 3 tonne.Its weight and size make it easy to transport, fit and offers a financially economical option.

Digga double pin hitch

The double pin fixtures make it ideal for augering and screw anchoring in all ground conditions. It is suitable for all drive unit ranges from PDD to PD50, Supa Drives, Mega Drives, Ultra Drives and Xtreme Drives.

The double pin hitch also comes in a 'swing control system', which includes forward and aft dampening for safer maneuvering around worksites and better control of the auger. It suits PD3-PD50 drive units and effectively increases operator productivity and reduces cost.

Digga cradle hitch

It is available with loose pin or fixed pin options and suitable for PDD – PD50 drives. There is more information on the benefits of using the Digga cradle hitch, here.

Digga piling / ryno hitch

The piling hitch cradles the drive in 3 different positions to give better control and manoeuvrability when moving around the job site as well as easier connectivity to augers and screw piles.

As it has been designed for screw piling, it is suited to larger drive units from PD12 – PD50, Supa Drives, Mega Drives, Ultra Drives and Xtreme Drives.

There is more information on the benefits of using the piling cradle hitch, here.

Ordering your excavator hitch and supplying the correct measurements

When you’re ordering a hitch for your attachment it’s important you supply the correct details to ensure your hitch fits the machine and application.

You will need to take some measurements of bucket and supply: machine make and model and your Digga attachment part number.

To order your excavator hitch you can complete the details on the Digga website, here.

See the reference diagrams below. These are also available within the online order form and highlight where to take the measurements from.

Comments

Post a Comment