Digga tips - best practice to increase the life of your wearparts.

The cutting teeth & pilot on any auger are wear parts and you can increase the life of them with the help of Digga's best practice tips.

The wear life of a tooth or pilot is undefinable. They will be affected by how often they are used, how they are looked after and the ground conditions they are being used in.

To assist with peak performance and longevity of the wear parts there are a few procedures that can be carried out that will help prolong the life of wear parts and increase drilling efficiency.

To help increase the life of your wear parts, you can:

If you over use your wear parts it will ultimately slow you down and potentially cause damage to your auger, auger flights and auger drive. Keep your wear parts clean and in-check and keep working efficiently!

For more information on our range of wearparts please visit www.digga.com/auger-wearparts

The wear life of a tooth or pilot is undefinable. They will be affected by how often they are used, how they are looked after and the ground conditions they are being used in.

For example, in non-fracturable ground where the rock is reduced to a powder; the powder is likely to get caught in and around the cutting head and, acting like a sand paper, will wear away both the pocket and the tooth. In hard ground conditions such as rock over heating within the hole can cause the ground to glaze over. The heat will polish the rock making it harder and have a greater influence on the wear of your cutting heads.

To assist with peak performance and longevity of the wear parts there are a few procedures that can be carried out that will help prolong the life of wear parts and increase drilling efficiency.

To help increase the life of your wear parts, you can:

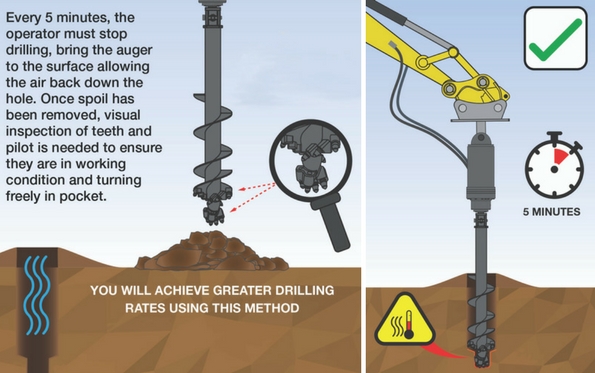

Grinding, cutting and drilling rock will generate heat due to the friction between the two substances. It is good practice to periodically remove the auger from the hole and also add water.

We recommend every 4 to 5 minutes lifting the auger out of the hole to allow cooler air into the hole and the hot air to exit.

The use of water has a dual effect, not only assisting in cooling the cutting face, but by binding the dry loose material together for easier spoil removal.

We recommend every 4 to 5 minutes lifting the auger out of the hole to allow cooler air into the hole and the hot air to exit.

The use of water has a dual effect, not only assisting in cooling the cutting face, but by binding the dry loose material together for easier spoil removal.

- Ensure the pick tooth is rotating freely in the pocket.

If there is a lot of dirt or spoil around the pick tooth, it will eventually stop rotating. As you check the tooth pick heads and clear off spoil, also check that it can rotate freely. If your pick tooth has been rotating as it should, it will look like it has been in a pencil sharpener. If there are any flat spots then this is an indication that the tooth has been jammed and is not rotating. A good method to free up the teeth is to hit the tooth or pocket with a hard plastic or copper hammer. If this does not free up the tooth then you may need to remove the tooth, clear the debris and refit it. Check this out for more info.

Ensuring a straight hole is drilled by adjusting the arc of the excavator boom when drilling into the ground ensures there is no side load put on the auger which can bend the auger and cause damage to the head, pilot and teeth.If you over use your wear parts it will ultimately slow you down and potentially cause damage to your auger, auger flights and auger drive. Keep your wear parts clean and in-check and keep working efficiently!

For more information on our range of wearparts please visit www.digga.com/auger-wearparts

Comments

Post a Comment